Fibreglass

The resin has almost no strength without fibreglass. It is available in sheets of

'chopped strand mat' (CSM). It is also possible to buy just chopped strands, and to

mix them with the resin. This is useful for the magnet rotor castings. Add a little

resin to the fibreglass, and press out all the air bubbles, before adding more resin.

Talcum powder

Talcum powder is a cheap filler which can be mixed with the resin after the peroxide

has been added. It makes the resin mixture much cheaper, and a little thicker. Resin

can be mixed with up to twice its own weight of talcum powder. The powder also

helps to reduce the heat build-up in large resin castings.

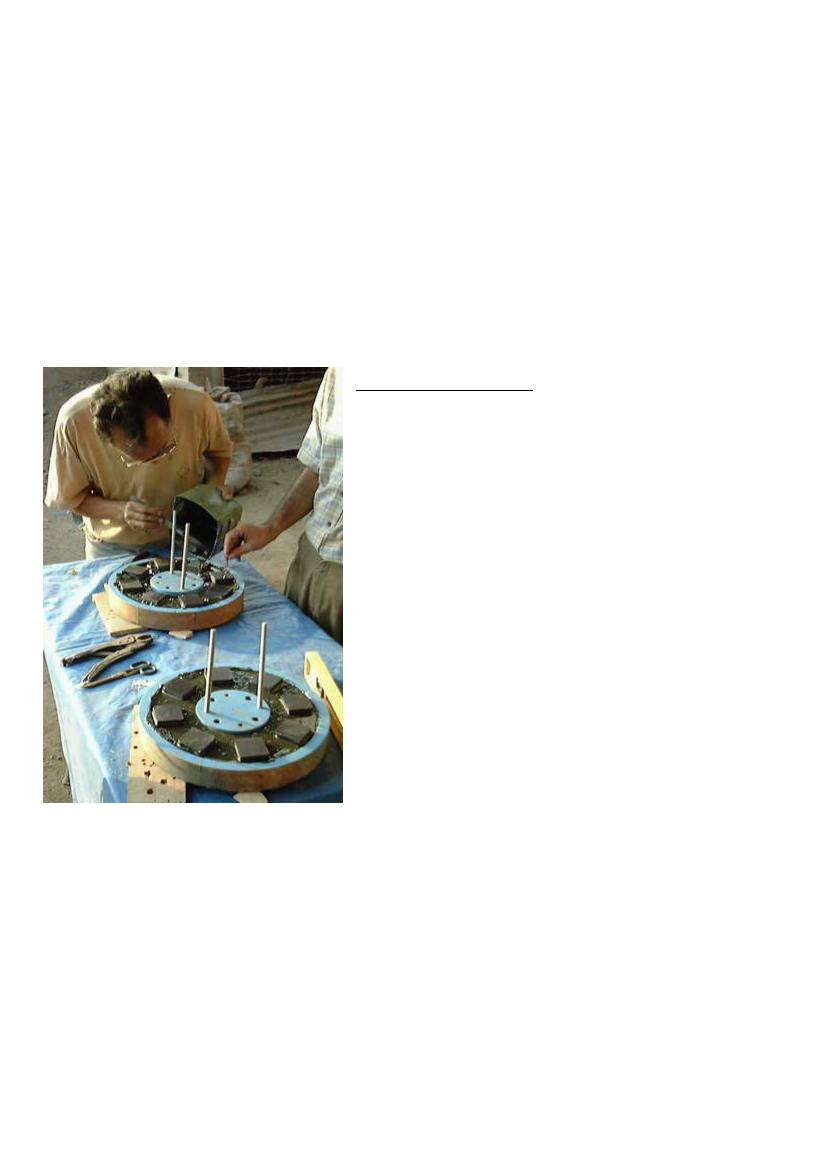

Using painted moulds in Peru

Mould preparation

Polyurethane varnish

Ordinary paint should not be used on moulds.

Better to use nothing. If possible, use

polyurethane varnish. This will prevent moisture

coming out of a mould made from wood, plaster

or clay. Smooth the varnish off with sandpaper

before polishing it.

Polish

Polish the mould several times before using it

first time. Rub all the polish off with a rag and

then leave it some hours and do it again.

Silicone polish is not compatible with PVA

release agent. Use wax polish.

PVA Release agent

Paint this over the mould and let it dry. It forms

a sheet of PVA, which greatly helps to separate

the casting from the mould.

PMG manual

page 50

June 2001